pillowcase factories

Ліст . 19, 2024 23:35 Back to list

pillowcase factories

The Evolution and Significance of Pillowcase Factories

Pillowcases are often overlooked household items, but they play a critical role in our daily lives. They protect our pillows, contribute to our comfort while we sleep, and reflect our personal style through diverse designs and fabrics. Behind this seemingly simple product lies a complex industrial process, exemplified by pillowcase factories that have evolved significantly over time.

Historically, pillowcases were crafted by hand, often from available domestic materials. The invention of the sewing machine in the 19th century revolutionized textile production, leading to the establishment of factories that could produce textiles on a larger scale. This technological advancement laid the groundwork for what would become the modern pillowcase manufacturing industry.

Pillowcase factories operate under a systematic process that begins with the selection of raw materials. Cotton, linen, polyester, and blends are among the most common fabrics used today. Factories must balance considerations such as durability, hypoallergenic properties, and comfort when choosing materials. Cotton remains a popular choice due to its softness and breathability, while polyester is favored for its affordability and durability. As sustainability becomes a growing concern, there is also a burgeoning market for organic cotton and bamboo fiber pillowcases, reflecting consumer demand for eco-friendly products.

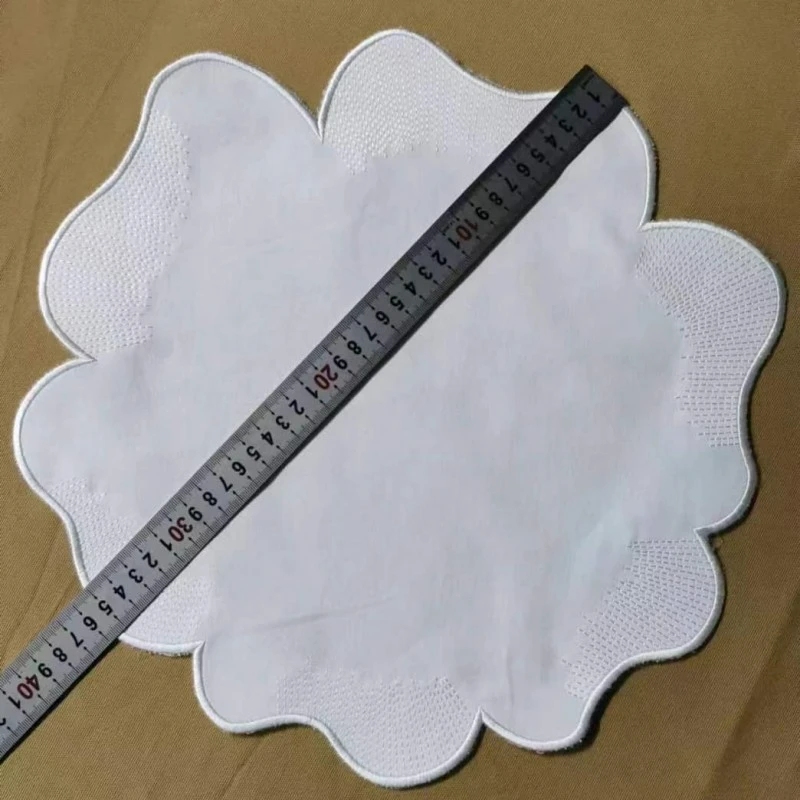

Once the material is selected, the cutting phase begins. Large rolls of fabric are layered and fed into cutting machines that slice them into the appropriate sizes for pillowcases. This stage requires precision to ensure that all pieces are uniform, which is critical for maintaining quality control in the final product. Advanced technology, including laser cutting, has further increased efficiency and accuracy in this phase, minimizing waste and maximizing productivity.

Next, the cut fabric pieces move to the sewing department, where they are meticulously stitched together to form pillowcases. This process can be mechanized, with sewing machines operating at high speeds, or it can involve skilled seamstresses working by hand, especially for custom designs. Each factory may have its own unique assembly lines depending on the styles and quantities of pillowcases being produced.

pillowcase factories

Quality control is a vital component of any manufacturing process, and pillowcase factories are no exception. Each pillowcase undergoes inspection for defects such as uneven stitching, fabric flaws, or incorrect dimensions. This quality assurance is essential, as flawed products can lead to customer dissatisfaction and impact a company's reputation. Many factories adhere to strict industry standards, and some even pursue certifications to demonstrate compliance with environmental and labor regulations.

The design aspect of pillowcase manufacturing has also evolved significantly. In the past, designs were limited due to the simplicity of the printing techniques available. However, advancements in digital printing have opened new avenues for creativity. Factories can now offer an array of designs, from classic floral patterns to contemporary geometric prints, catering to diverse consumer preferences. Customization options are also increasingly popular, allowing customers to create pillowcases with personalized images or text.

Pillowcase factories are not merely places of production; they also play a significant role in the local economy. They provide job opportunities, from factory workers to management positions, and contribute to a community's economic health. Moreover, many factories are part of larger supply chains, supporting a variety of related industries, including textile manufacturing, shipping, and retail.

As globalization continues to influence the manufacturing landscape, many pillowcase factories have also adapted. Some have opted to offshore parts of their production processes to countries where labor is less expensive. However, there is a growing movement toward reshoring, as consumers increasingly value domestic production for quality assurance and shorter shipping times. This trend reflects a broader shift in consumer consciousness, where ethical manufacturing practices and sustainability are paramount.

In conclusion, pillowcase factories are a fascinating blend of tradition and innovation. They embody the evolution of textile manufacturing and play a vital role in meeting consumer needs. As these factories continue to adapt to emerging trends in sustainability and customization, they remain integral to the way we experience comfort in our homes. The next time you rest your head on a soft, stylish pillowcase, take a moment to appreciate the complex journey it undertook to enhance your everyday life.

-

100% Stonewashed French Linen Bed Sheets | Soft Luxury

NewsAug.04,2025

-

Premium Linen Pajama Set: Comfort & Style | GPT-4-Turbo

NewsAug.03,2025

-

Wholesale Bamboo Bed Sheet Sets | Eco-Luxury Comfort

NewsAug.01,2025

-

Premium Stone Washed Fabric - Soft & Durable Style

NewsJul.31,2025

-

Authentic Handcrafted Indian Block Print Napkins | Shop Artisan Style

NewsJul.31,2025

-

Premium Bath Towel for Home & Hotel Use - Soft & Absorbent Bathtowel

NewsJul.30,2025